![]()

![]()

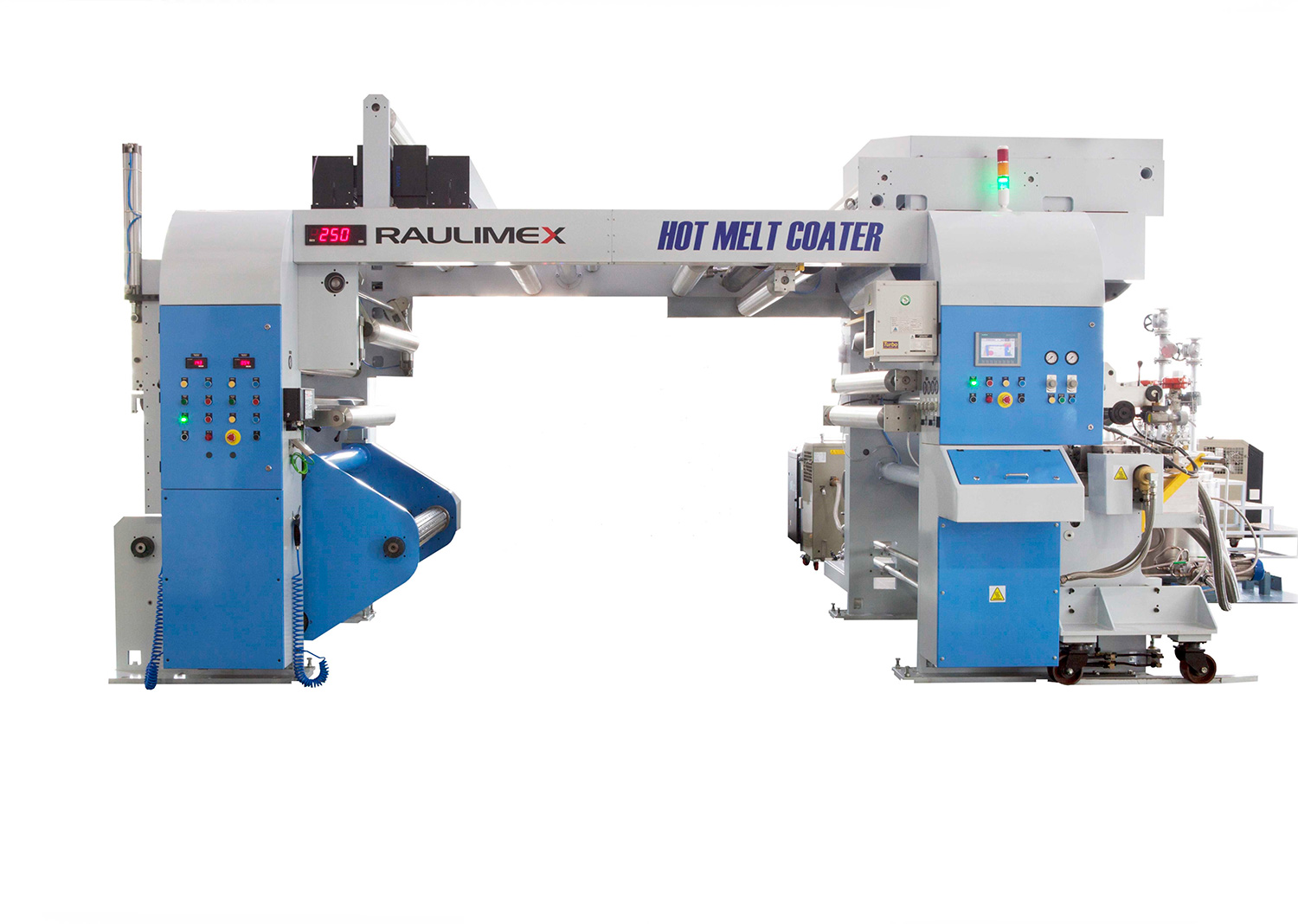

Mechanical speed up to 250 m / min.

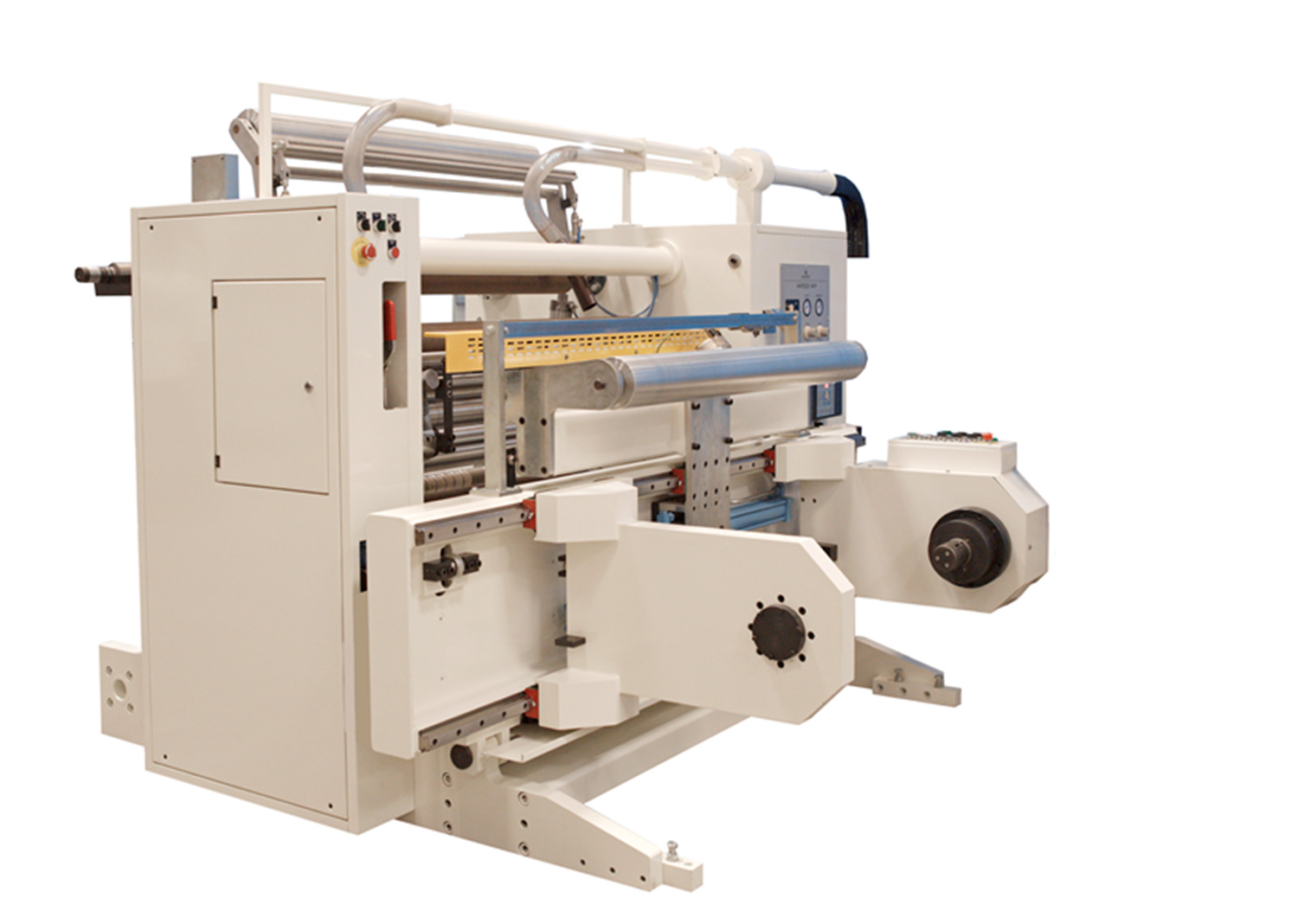

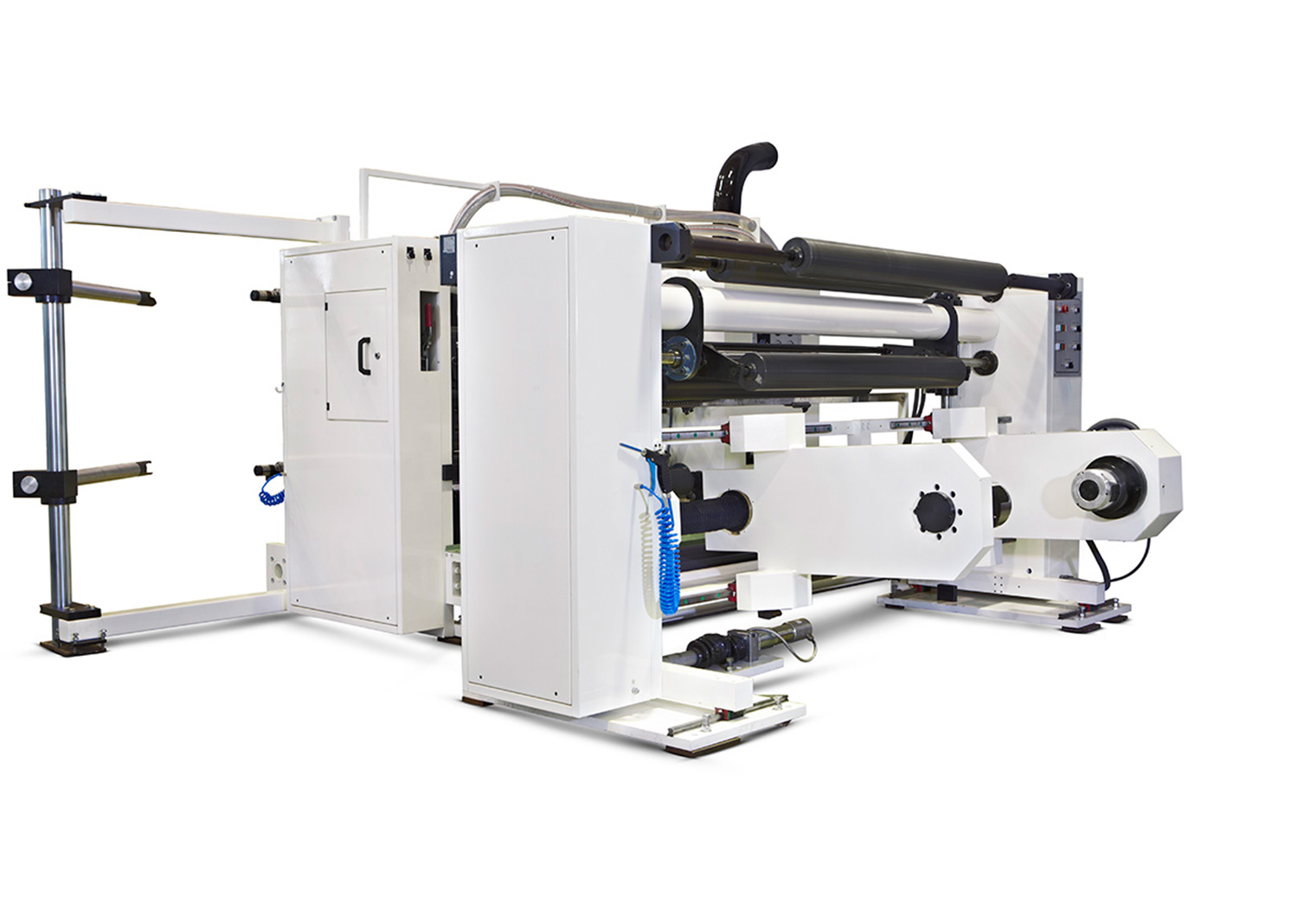

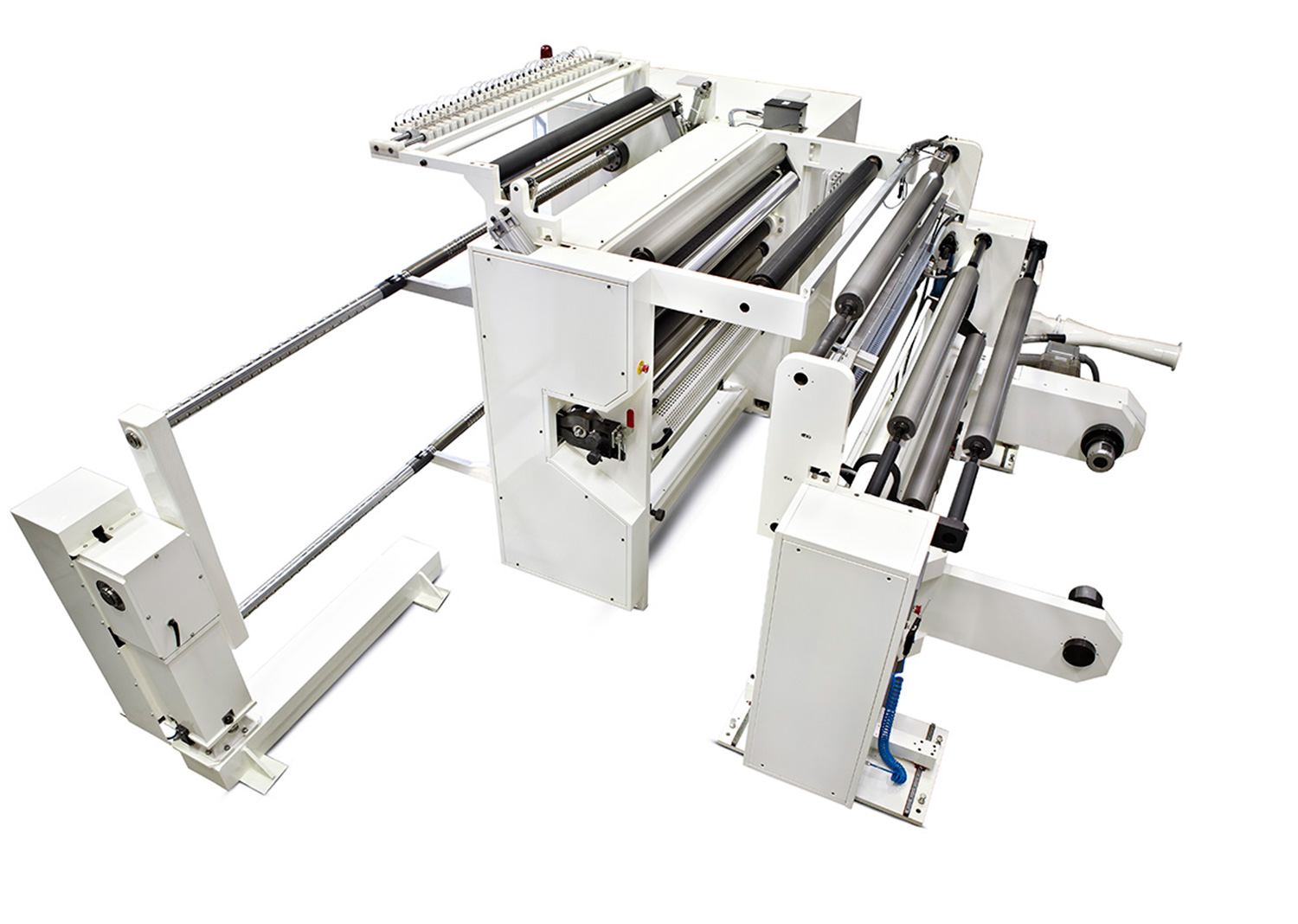

Printing repeat up to 750 mm.

Trolleys with printing cylinder & ink system.

The Super Sprint is an economic model that has all the essential features required to give quality print that is equal to those produced by the best in the industry. Its efficient short dryer with machine integrated thermal heat exchangers makes it very compact for the speed it can deliver.

Super Sprint ELS-C: in this model the printing cylinder is held on taper chucks.